SS 310S Sheet and Coils exporter

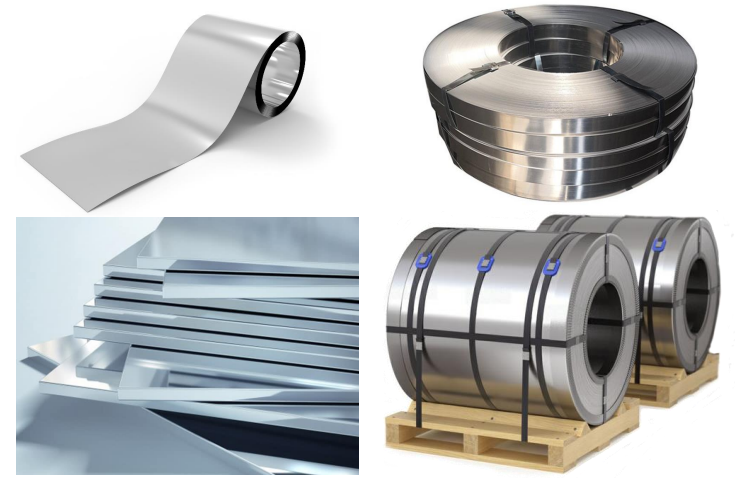

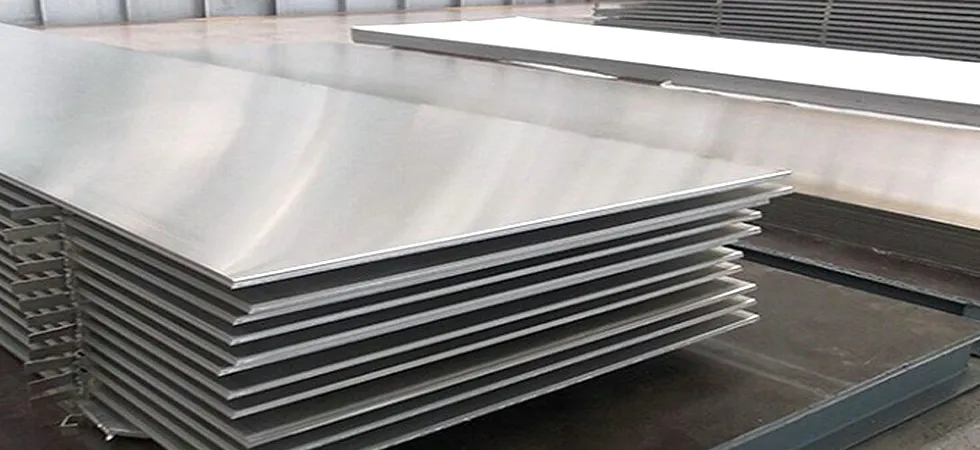

SS 310S Sheet and Coils exporter specializes in supplying high-quality stainless steel products designed for demanding industrial environments. These sheets and coils are manufactured from grade 310S stainless steel, known for its excellent resistance to oxidation and corrosion at elevated temperatures. The material’s superior mechanical properties make it ideal for applications requiring durability and heat resistance. Our offerings include precision-rolled sheets and tightly wound coils that meet stringent international standards to ensure reliability and performance.

The stainless steel 310S grade is an austenitic alloy containing high levels of chromium and nickel, which enhances its ability to withstand temperatures up to 1100°C. This makes it particularly suitable for use in heat exchangers, furnace parts, and kiln linings. The low carbon content in 310S minimizes carbide precipitation during welding, preserving corrosion resistance and structural integrity. These characteristics make the product a preferred choice for industries such as petrochemical, power generation, and aerospace.

Our sheets and coils are available in various thicknesses and widths, catering to customized industrial requirements. The flatness and surface finish of the products are maintained to facilitate easy fabrication, welding, and forming processes. Additionally, the coils can be supplied in both cold-rolled and hot-rolled conditions depending on the application needs. Each batch undergoes rigorous quality checks, including chemical composition analysis and mechanical testing, ensuring compliance with ASTM A240 and other relevant specifications.

With a robust export infrastructure, we ensure timely delivery of stainless steel sheets and coils to international markets. Packaging is designed to protect the material during transit, preventing damage from moisture and mechanical impact. Our logistics partners handle customs clearance and documentation efficiently, enabling smooth import processes for our clients. This export readiness allows us to serve a global clientele spanning the Middle East, Europe, and Asia.

Industrial buyers looking for reliable, high-performance stainless steel products will find our offerings well-suited for critical applications requiring heat and corrosion resistance. Whether for manufacturing components in chemical processing plants or constructing heat-resistant structures, our 310S stainless steel sheets and coils provide the necessary toughness and longevity. Partnering with a reputable supplier ensures access to certified materials backed by technical support and consistent quality assurance.

Lead Time

2–7 weeks depending on size

Delivery Terms

FOB, CIF, DDP

Shipping Modes

Sea / Air / Express

Why SS 310S Sheet and Coils exporter Are Preferred by Global Buyers

- ✔ Factory Pricing: Direct manufacturer rates with bulk stock

- ✔ Certified Quality: ISO & 3rd-party tested, EN 10204 certified

- ✔ Export-Ready: Sea-worthy packaging for on-time delivery

- ✔ Fast RFQs: Quick quotes for custom sizes & quantities

- ✔ Traceability: 100% heat number tracking from raw material to finished product

Trusted by industries like oil & gas, petrochemicals, power, marine, and heavy engineering.

- Manufacturing Capacity: 500 MT / Month

- Export Experience: 15+ Years

- Countries Served: 50+

- Annual Export Volume: 5,500 MT

Table of Contents

- 1. What is SS 310S Sheet and Coils exporter

- 2. How to Choose the Right Manufacturer

- 3.Comparison of SS 310S Sheet and Coils exporter

- 4. Why Global Buyers Source from Jainam Ferro Alloys

- 5. Features

- 6. Technical Overview

- 7. Specifications

- 8. Available Grades

- 9. Available Sizes

- 10. Chemical Properties

- 11. Mechanical Properties

- 12. Physical & Thermal Properties

- 13. Electrical Resistivity

- 14. Equivalent Grades

- 15. Manufacturing Process & Heat Treatment

- 16. Various Types

- 17. Applications & Uses

- 18. Industries We Serve

- 19. Latest Price List

- 20. MOQ & Payment Terms

- 21. Export Packaging & Shipping

- 22. Cities We Supply in India

- 23. Countries We Export Worldwide

- 24. Our Certifications

- 25. Quality Inspection & Testing

- 26. Our Other Product Types

- 27. People Also Search For

- 28. Frequently Asked Questions

- 29. About Jainam Ferro Alloys

How to Choose the Right SS 310S Sheet and Coils exporter

India is home to hundreds of manufacturers ranging from small job shops to large ISO-certified exporters. International and domestic buyers typically evaluate manufacturers based on quality compliance, production capacity, export experience, and pricing transparency.

- Certification & international standards (ASME, ASTM, EN)

- Manufacturing capability vs trading activity

- Export documentation & inspection support

- Stock availability & lead time reliability

- Past supply experience in oil & gas, EPC & heavy industries

Comparison Factors Among SS 310S Sheet and Coils exporter

| Evaluation Factor | Small Local Suppliers | Trading Companies | ISO-Certified Manufacturers |

|---|---|---|---|

| Manufacturing Control | Limited | None | Full in-house / audited partners |

| International Standards | Basic | Depends on source | ASME / ASTM / EN |

| Inspection & MTCs | Limited | Inconsistent | EN 10204 3.1 / 3.2 |

| Export Experience | Low | Medium | 50+ countries |

| Risk for EPC Projects | High | Medium | Low |

International buyers typically prefer ISO-certified manufacturers for large-scale or critical applications due to better quality control, documentation, and lower project risk.

Why Global Buyers Choose Jainam Ferro Alloys

Jainam Ferro Alloys is a trusted ISO 9001:2015 certified manufacturer and global exporter of ferro alloys and metal products, supplying consistent, high-quality materials to customers across USA, UK, Europe, Middle East, Africa, and Asia-Pacific. Our focus on quality assurance, cost efficiency, and on-time delivery makes us a preferred sourcing partner for international buyers.

| Key Advantage | Buyer Benefit |

|---|---|

| ISO 9001:2015 Certified Manufacturing | Consistent quality with documented QA systems and process control |

| ASME / ASTM / EN Compliant Products | Globally accepted standards with EN 10204 3.1 / 3.2 MTCs |

| Lower Manufacturing & Sourcing Costs | Save up to 15–20% compared to European suppliers |

| Favorable Exchange Rate Advantage | Reduced landed cost for international importers |

| In-House Testing & Inspection Facilities | Strict chemical, mechanical & dimensional quality checks |

| Bulk Stock & High Production Capacity | Fast order fulfillment and stable supply for large projects |

| Custom Sizes & Drawing-Based Manufacturing | Products manufactured exactly to buyer specifications |

| Export-Grade Packaging & Global Logistics | Sea-worthy packing, palletization & worldwide shipping support |

| Faster Global Shipping Routes | Optimized logistics for Middle East, Africa & Southeast Asia |

| Technical & After-Sales Support | Project assistance, documentation & responsive RFQ handling |

| Trusted by Global Steel & EPC Companies | Proven export experience across 50+ countries |

Features of SS 310S Sheet and Coils

- ✔ Excellent high-temperature strength and oxidation resistance

- ✔ Superior corrosion resistance in a variety of environments

- ✔ Good weldability and fabricability with minimal post-weld heat treatment

- ✔ Exceptional resistance to scaling and thermal fatigue

- ✔ High nickel and chromium content for enhanced performance

- ✔ Available in various thicknesses and dimensions to meet specific needs

Technical Overview of SS 310S

| Product | Composition | Usage | Standards |

|---|---|---|---|

| SS 310S Sheet | Cr 24%, Ni 19%, C 0.08%, Mn 2%, Si 1.5% | High-temperature applications, furnace parts, heat exchangers | AISI 310S, ASTM A240, UNS S31008 |

| SS 310S Coil | Cr 24%, Ni 19%, C 0.08%, Mn 2%, Si 1.5% | Chemical processing, petrochemical industries, power generation | AISI 310S, ASTM A240, UNS S31008 |

| SS 310S Plate | Cr 24%, Ni 19%, C 0.08%, Mn 2%, Si 1.5% | High-temperature structural applications, oil and gas pipelines | AISI 310S, ASTM A240, UNS S31008 |

Specifications Table

| Material | Stainless Steel 310S |

|---|---|

| Grades | 310S |

| Standard | AISI, ASTM, UNS S31008 |

| Size Range | 0.5 mm to 20 mm thickness, Width up to 2000 mm |

| Length | Up to 6000 mm |

| Form | Sheets and Coils |

Available Grades Table

| Product | Composition | Applications |

|---|---|---|

| SS 310S Sheet | Ni: 19-22%, Cr: 24-26%, C: ≤0.08% | High-temperature applications, furnace components, heat exchangers |

| SS 310S Coil | Ni: 19-22%, Cr: 24-26%, C: ≤0.08% | High-temperature furnaces, petrochemical processing, chemical equipment |

| SS 310S Plate | Ni: 19-22%, Cr: 24-26%, C: ≤0.08% | Gas turbine components, industrial furnace parts, thermal processing equipment |

| SS 310S Strip | Ni: 19-22%, Cr: 24-26%, C: ≤0.08% | Oil and gas industry, boiler components, exhaust systems |

| SS 310S Foil | Ni: 19-22%, Cr: 24-26%, C: ≤0.08% | Heat shield applications, thermal insulation, aerospace components |

Available Sizes of SS 310S Sheet and Coils (MM)

| Size (MM) | Size (MM) |

|---|---|

| 0.5 | 1.0 |

| 1.5 | 2.0 |

| 2.5 | 3.0 |

| 3.5 | 4.0 |

| 4.5 | 5.0 |

| 5.5 | 6.0 |

| 6.5 | 7.0 |

| 7.5 | 8.0 |

| 8.5 | 9.0 |

| 9.5 | 10.0 |

Chemical Properties of SS 310S

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.25 max |

| Manganese (Mn) | 2.00 max |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.030 max |

| Silicon (Si) | 1.00 max |

| Chromium (Cr) | 24.00 - 26.00 |

| Nickel (Ni) | 19.00 - 22.00 |

| Molybdenum (Mo) | 0.75 max |

Mechanical Properties of SS 310S

| Property | Value |

|---|---|

| Tensile Strength (MPa) | 520 |

| Yield Strength (MPa) | 205 |

| Elongation (%) | 40 |

| Hardness (HB) | 200 |

| Modulus of Elasticity (GPa) | 200 |

SS 310S Sheet and Coils – Physical & Thermal Properties

Density of SS 310S Sheet and Coils

| Property | Metric | Imperial |

|---|---|---|

| Density | 7.90 g/cm³ | 0.285 lb/in³ |

Melting Point of SS 310S Sheet and Coils

| Property | Metric | Imperial |

|---|---|---|

| Melting Point | 1400 - 1450 °C | 2552 - 2642 °F |

Specific Heat of SS 310S Sheet and Coils

| Specific Heat of SS 310S Sheet and Coils | ||

|---|---|---|

| Specific Heat (J/kg·K) | Temperature Range (°C) | Condition |

| 500 | 20 - 100 | Solid |

| 520 | 100 - 600 | Solid |

| 550 | 600 - 800 | Solid |

Electrical Resistivity of SS 310S

| Electrical Resistivity | ||

|---|---|---|

| Value (µΩ·m) | Temperature (°C) | Treatment or Condition |

| 750 | 20 | Annealed |

| 770 | 100 | |

| 790 | 200 | |

| 820 | 300 | |

| 850 | 400 | |

Manufacturing Process & Heat Treatment of SS 310S

Annealing

Annealing of SS 310S involves heating the material to a temperature range of 1000-1150°C, followed by controlled cooling. This process helps to relieve internal stresses, improve ductility, and enhance the material's overall mechanical properties.

Forging

Forging of SS 310S is performed at elevated temperatures, typically between 1050-1200°C. This process improves the material's grain structure and mechanical properties, making it suitable for high-temperature applications.

Hardening & Tempering

| Process | Temperature Range (°C) | Quenching Medium | Purpose |

|---|---|---|---|

| Hardening | 1000-1100 | Oil or Water | To increase hardness and strength |

| Tempering | 600-800 | Air | To reduce brittleness and improve toughness |

| Stress Relieving | 600-700 | Air | To relieve residual stresses after hardening |

The combination of these processes ensures that SS 310S exhibits excellent mechanical properties and performance in high-temperature environments, making it a preferred choice for various industrial applications.

Various Types

SS 310S Hot Rolled Sheet

- Thickness: 1.0 mm to 10.0 mm

- Condition: Hot Rolled

- Applications: Chemical processing, High-temperature applications

SS 310S Cold Rolled Coil

- Thickness: 0.5 mm to 3.0 mm

- Condition: Cold Rolled

- Applications: Food processing, Pharmaceutical equipment

SS 310S Annealed Sheet

- Thickness: 0.8 mm to 12.0 mm

- Condition: Annealed

- Applications: Architectural applications, Heat exchangers

SS 310S Polished Coil

- Thickness: 0.6 mm to 5.0 mm

- Condition: Polished

- Applications: Decorative applications, Kitchen equipment

Applications & Uses

- Oil & Gas Industry

- Petrochemical Plants

- Water Treatment Plants

- Pharmaceutical Industry

- Food & Beverage Industry

- Automobile Industry

Industries We Serve

Our alloys are widely used across:

- Steel Plants

- Foundries & Casting Units

- Automobile Industry

- Shipbuilding & Marine

- Oil & Gas

- Engineering Components

- Heavy Industrial Machinery

latest Price List of SS 310S Sheet and Coils

| Material Grade | Thickness | Price (USD / Kg) | Price (INR / Kg) |

|---|---|---|---|

| SS 310S | 3 mm | $3.50 – $4.00 | ₹290 – ₹340 |

| SS 310S | 6 mm | $3.20 – $3.80 | ₹260 – ₹320 |

| SS 310S | 10 mm | $3.00 – $3.50 | ₹240 – ₹290 |

Note: Prices are indicative and may vary based on size, quantity, raw material cost, and delivery location. Contact us for the latest quotation for SS 310S Sheet and Coils.

MOQ & Payment Terms

Minimum Order Quantity: 25–100 Kg depending on part size and grade.

Payment Terms: Depending On Grade and Quantity Size

Export Packaging & Shipping

- Seaworthy, fumigated wooden crates with waterproof inner lining

- Palletised packing with clear shipping marks and heat number identification

- Container stuffing supervision with loading photographs available on request

Cities We Suppllied In India

| Supply Cities | |||||

|---|---|---|---|---|---|

| Mumbai | Delhi | Pune | Chennai | Hyderabad | Bengaluru |

| Ahmedabad | Rajkot | Coimbatore | Kolkata | Bhopal | Surat |

We exported to 50+ countries worldwide.

| Exported Countries | |||||

|---|---|---|---|---|---|

| USA | UK | UAE | Germany | South Africa | Australia |

| Italy | Canada | Netherlands | Qatar | Saudi Arabia | Malaysia |

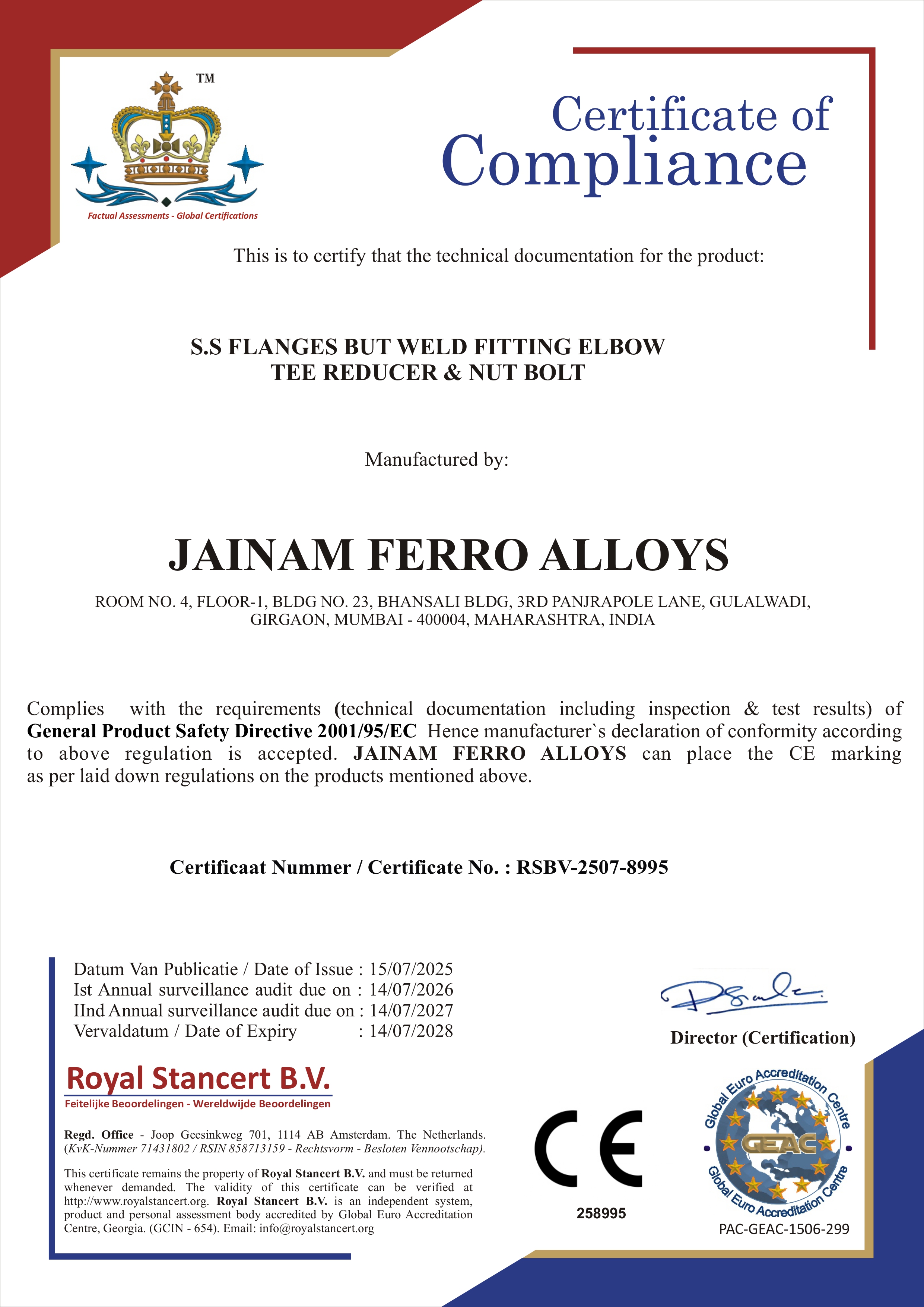

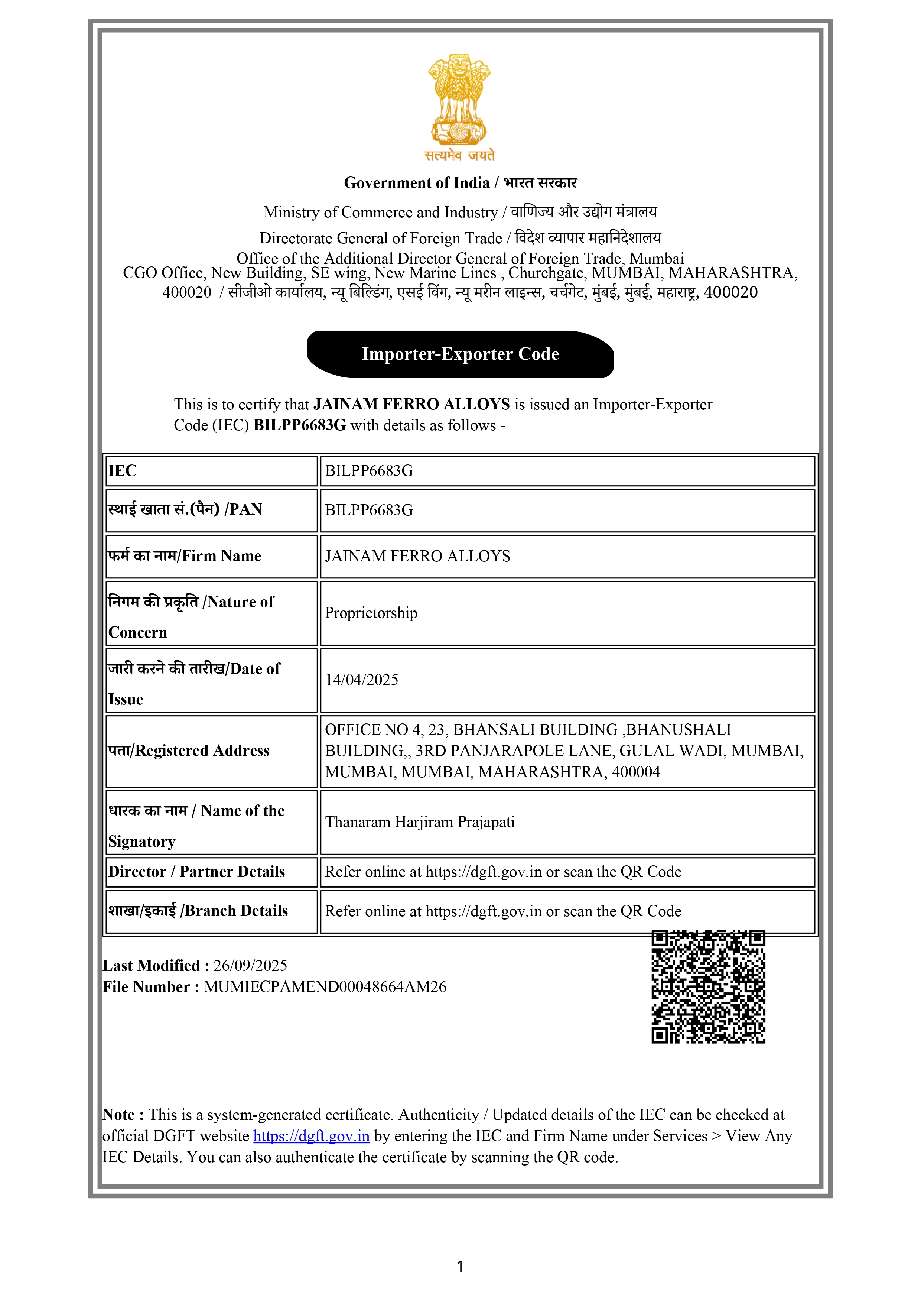

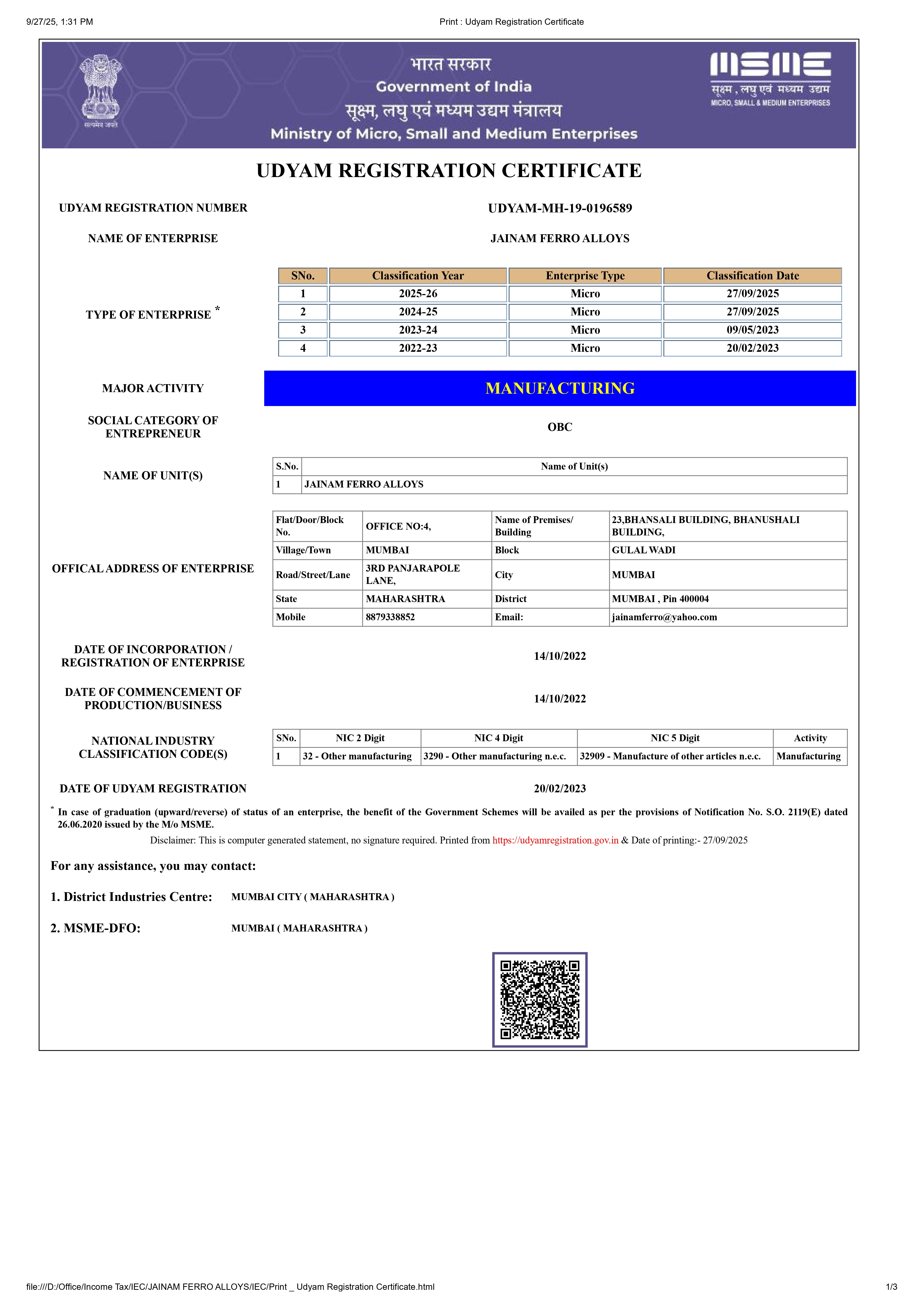

Our Certifications

We are a certified manufacturer and exporter, committed to strict quality control and international compliance standards. Below are our key certifications.

Compliance

ISO 14001:2015

Importer Exporter

ISO 45001:2018

ISO 9001:2015

Udyam Registration

Quality Inspection & Testing

At Jainam Ferro Alloys, all products are checked through strict quality inspection and testing to meet international standards such as ASTM, ASME, EN, and DIN. This ensures consistent quality, accurate dimensions, and full material traceability.

- ✔ Chemical composition testing

- ✔ Mechanical tests such as tensile and hardness

- ✔ Dimensional inspection as per standard tolerances

- ✔ PMI, ultrasonic, and visual inspection (if required)

- ✔ EN 10204 3.1 / 3.2 test certificates

- ✔ Third-party inspection by SGS, TUV, BV, or Lloyd’s

Our quality systems support reliable supply for oil & gas, petrochemical, power, marine, and heavy engineering projects.

People Also Search For

- SS 310S Plate Supplier

- SS 310S Coil Manufacturer

- Stainless Steel 310S Sheet Price

- SS 310S Foil Exporter

- SS 310S Strip Wholesale

Frequently Asked Questions

About JAINAM FERRO ALLOYS

- ✔ Decades of experience in stainless steel, carbon steel, and alloy steel manufacturing

- ✔ ISO 9001:2015 certified company ensuring strict quality control standards

- ✔ Specialized in cold drawn pipes and tubes processing

- ✔ State-of-the-art manufacturing facilities with modern machinery

- ✔ Precision-engineered products with consistent quality and reliability

- ✔ Customized steel solutions as per client drawings and specifications

- ✔ Compliance with international industry standards

- ✔ Trusted supplier for critical industrial applications worldwide